|

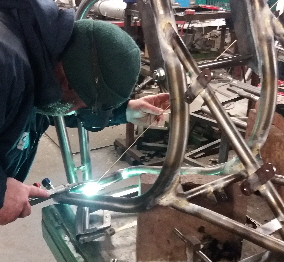

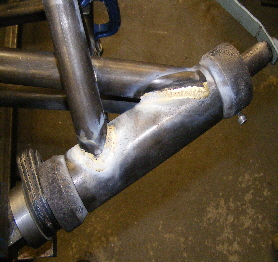

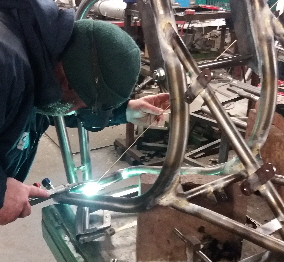

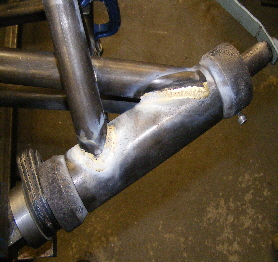

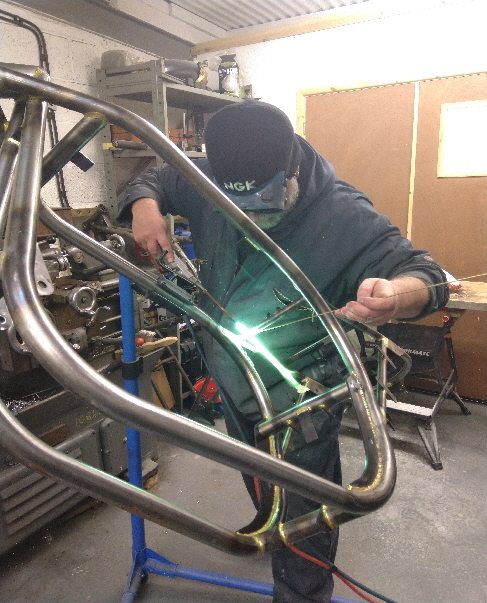

Bronze Welding

Bronze welding is a process of joining metals in which the edges of the metal are heated to a temperature below their melting point and a bronze alloy is simultaneously melted and caused to flow over the edges and join with them. By this means a strong and ductile union is produced between high melting point metals, i.e. cast iron, steel, copper and malleable iron etc.

Bronze welding resembles brazing up to a point, the application of brazing is generally limited to joints where a close fit or mechanical fastening serves to consolidate the assembly. In bronze welding the filler alone provides the joint strength, and is applied by the manipulation of a heating flame in the same manner as gas welding. The heating flame to serve the dual purpose of melting off the bronze filler and simultaneously heating the surface to be joined. the operator in this manner controls the work, hence the term "bronze welding".

It is considered that bronze welding is preferred/best form of welding on a frame as it provides a strong joint that allows an small amount flexi ideal for a bike frame.

|